11 juin 2025

AA-Biomasse Toploader in Oloron: A reduction of several thousand tons of CO2!

AABiomasse, Uniconfort and Dalkia: A New Biomass Boiler Plant in Oloron-Sainte-Marie for Renewable and Local Energy

AA-Biomasse has just completed the installation of its biomass toploader on a new biomass boiler plant located in Oloron-Sainte-Marie, a project led by Dalkia.

A reduction of more than 4,700 tons of CO2!

This project will prevent the emission of more than 4,700 tons of CO2 each year, the equivalent of more than 2,300 vehicles being taken off the road. This project is fully in line with the energy transition by promoting the production of renewable, local, and stable energy over the long term.

Powering industrial companies Lindt and Safran!

The biomass boiler plant, with the boiler from our partner Uniconfort, will power renowned industrial companies such as Lindt and Safran, by connecting them to the BOSC network. Thanks to this low-carbon energy source, these companies are strengthening their local roots and their long-term presence in the region. In addition, this project will create numerous local jobs in the energy transition sector and will enable communities and residents to benefit from renewable energy produced on site.

A Toploader Machine 100% Designed and Manufactured in France!

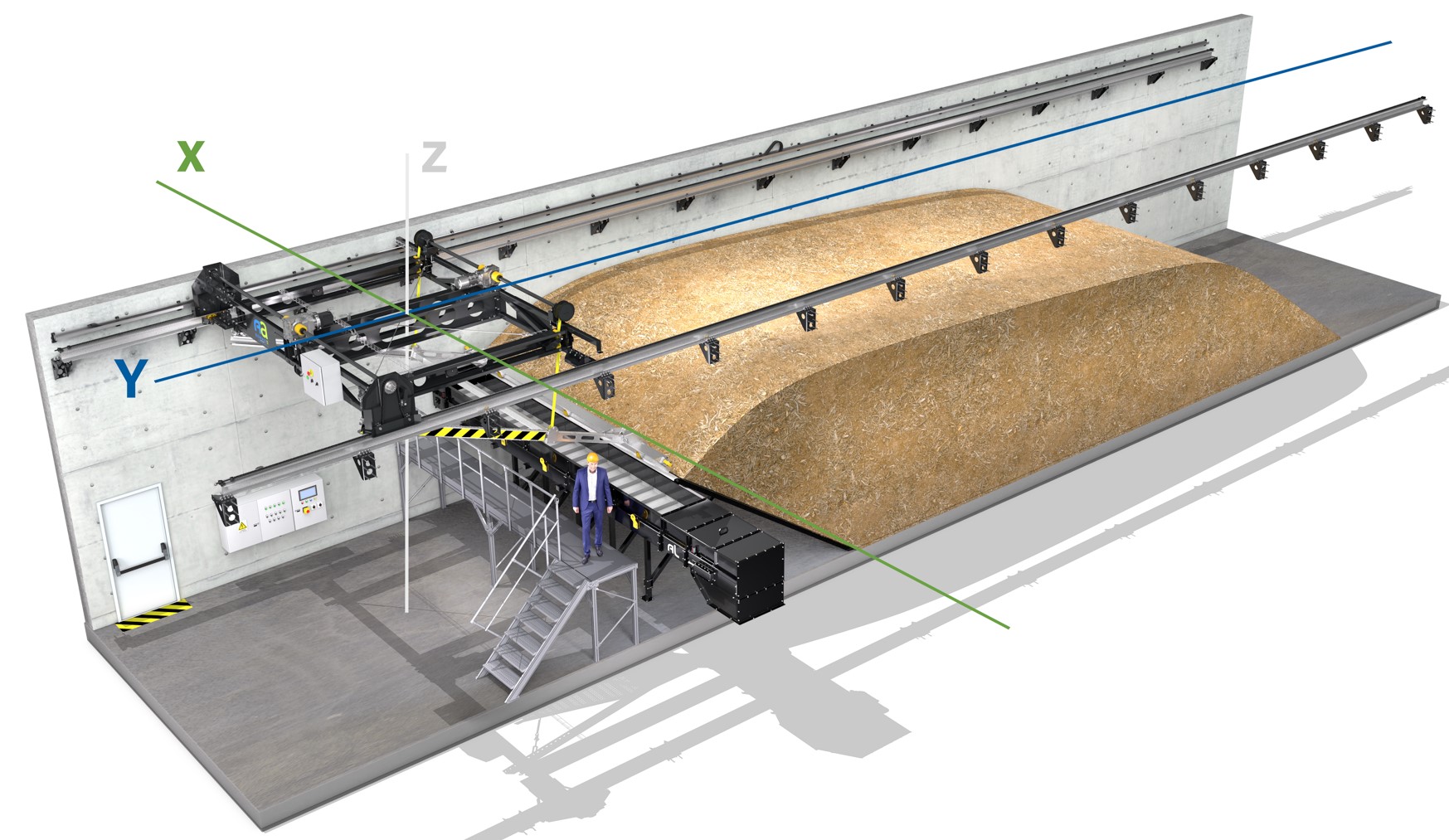

The "silo-rake" machine, more commonly known as a biomass toploader, plays a key role in this system. Designed and manufactured in France by the AA Biomasse teams, it enables the storage, automation, and delivery of biomass to the Uniconfort boiler. AA Biomasse controls the entire process, from design to installation monitoring, including manufacturing, installation, and commissioning, thus guaranteeing optimal performance.

This project is another source of great pride for the entire AA-Biomasse team, which is actively contributing to the energy transition in France.

Our "Toploader" silo, 100% designed and manufactured in France, allows for optimized and automatic storage of biomass as well as on-demand feeding of your boiler, regardless of the brand. This machine, which operates on the principle of a suspended rake, allows you to work the space taken up by your stock from above while leaving all the necessary space for your supply trucks, which can unload their material in record time!

Our biomass fields of activity

Biomass boiler room

Wood biomass boiler rooms represent an essential component of the current energy landscape, part of the transition towards more sustainable energy sources.

renewable energy

Biomass-based renewable energy processes encompass various technologies aimed at harnessing bio-based organic matter to produce energy sustainably.

Our biomass solutions

Biomass boiler room

renewable energy

Wood and biomass toploader Capacity 400 M3

Wood and biomass conveyor Flow rate 30 m3/h