Multi-Toploader Biomass

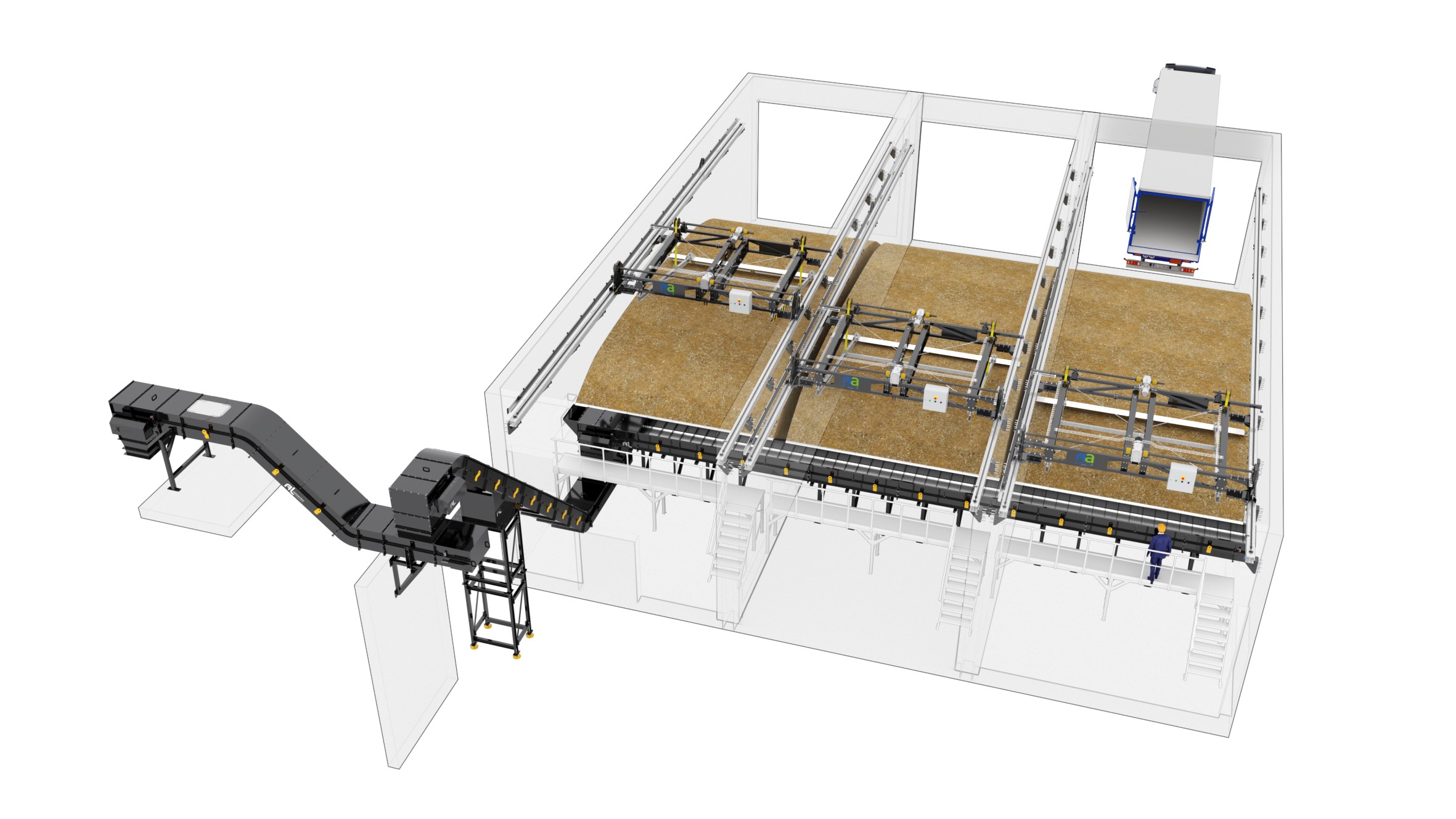

Multi-Toploader System with Through Conveyor — Modular, Continuous and Intelligent Storage

We offer an innovative assembly that allows for the installation of multiple Toploaders side-by-side, connected by a common through conveyor. This unique architecture provides a highly flexible, scalable, and secure biomass storage and feeding solution, perfectly suited to industrial facilities requiring large volumes and a continuous supply.

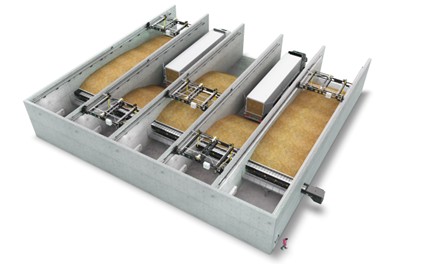

High-capacity and fully modular storage

By assembling multiple Toploaders, it becomes possible to:

significantly increase the available storage volume,

create several independent cells, each capable of receiving a different type of biomass or serving a specific function (quality, moisture content, origin, etc.),

adapt the configuration according to changes in the site, needs, or production.

Through conveyor: the heart of the system

The shared conveyor collects biomass from each cell, which is equipped with its own toploader.

This design offers several major advantages:

Truck unloading without line stoppage, even when one of the cells is being loaded,

Continuous feeding of boilers or process lines,

Optimal flow management, even with multiple toploaders operating in parallel.

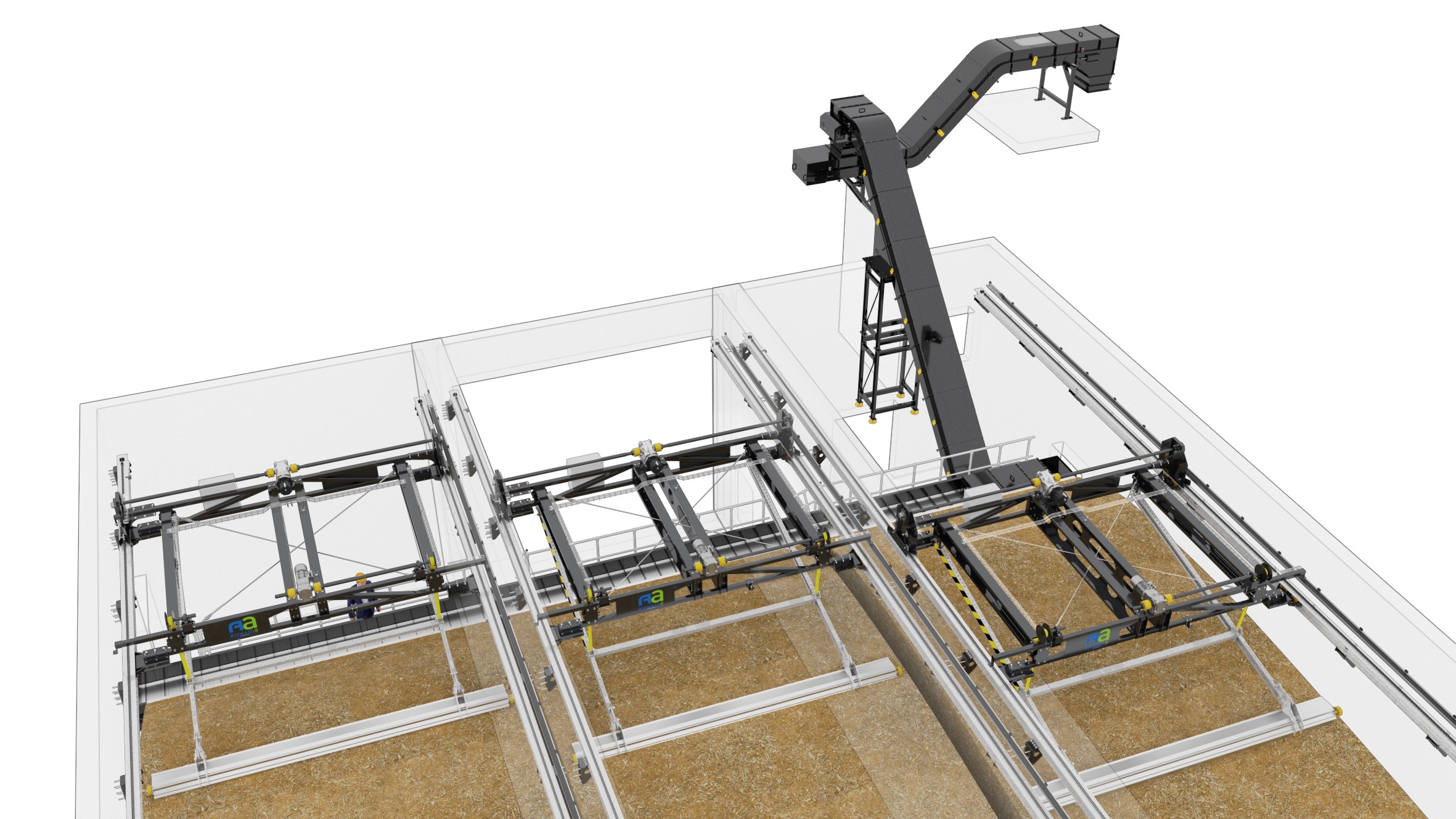

Intelligent material management: FIFO, mixing, and flexibility

Thanks to the multi-cell structure:

FIFO (First In – First Out) operation is possible to stabilize biomass quality.

The system also allows for the mixing of different materials (wood chips, shredded material, RDF, etc.) directly on the through conveyor. Since each cell can be controlled individually, the site benefits from an exceptional level of flexibility.

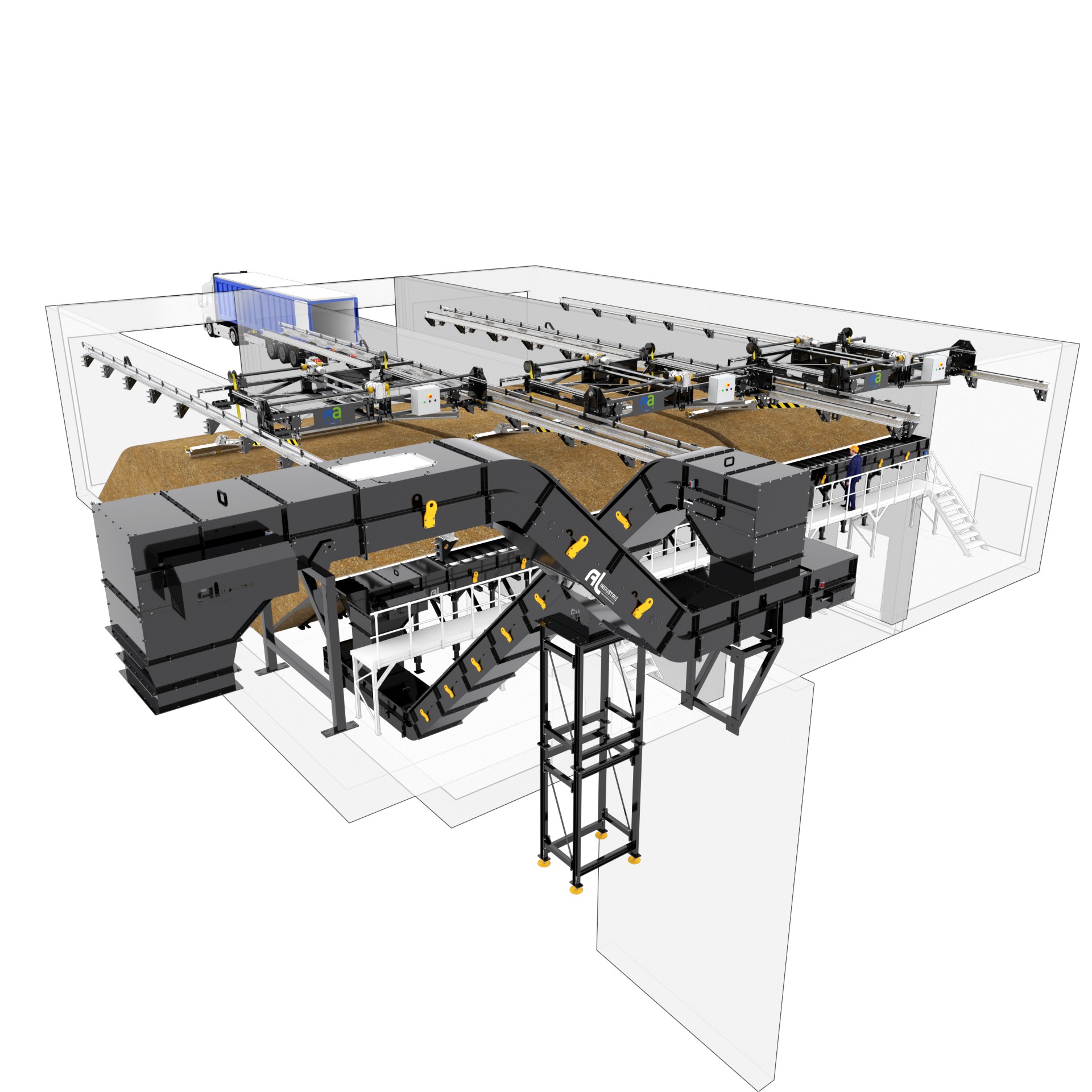

Maximum reliability thanks to machine redundancy

One of the major advantages of this setup is its complete redundancy:

If a toploader requires maintenance or experiences an interruption,

the other toploaders automatically take over,

No power outage impacts production or the boilers.

Very high-capacity storage

Multiple independent cells to organize and optimize flows

Continuous truck unloading without process disruption

FIFO management and material mixing capabilities

Secure supply thanks to machine redundancy

Scalable and modular architecture to suit site needs