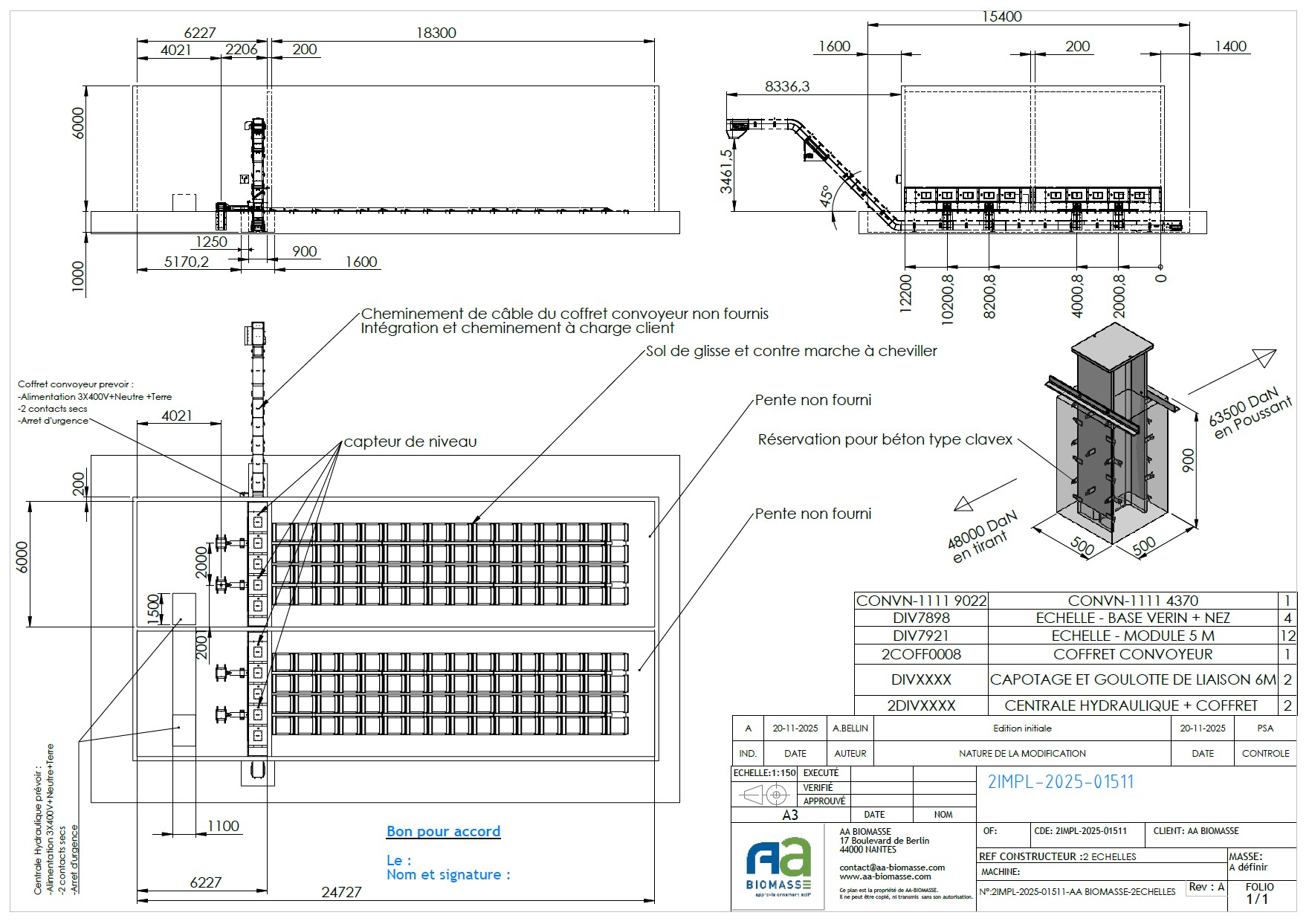

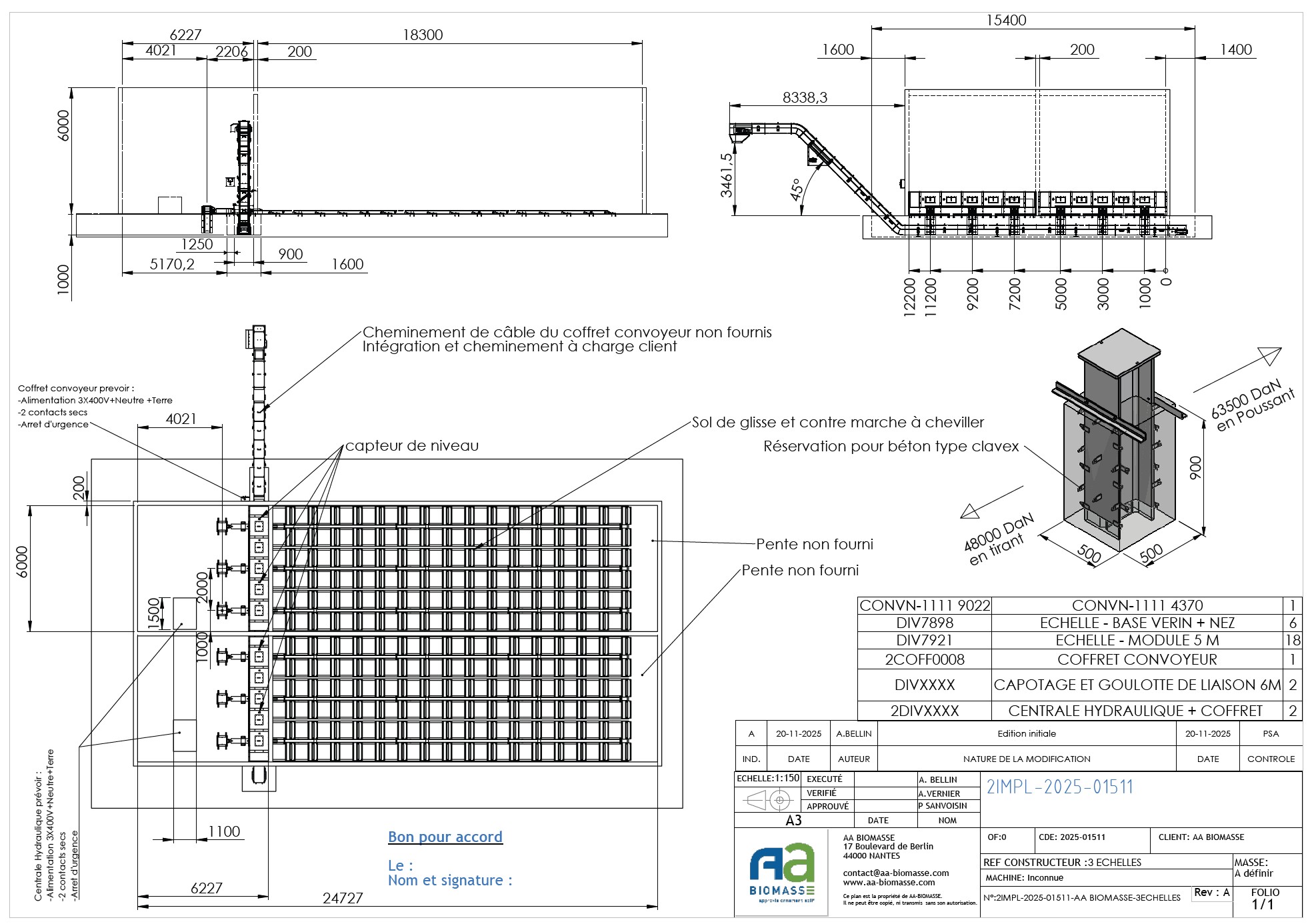

Biomass drive-through ladders

Drive-Through Silo — Direct Truck Storage and Automated Biomass Feeding

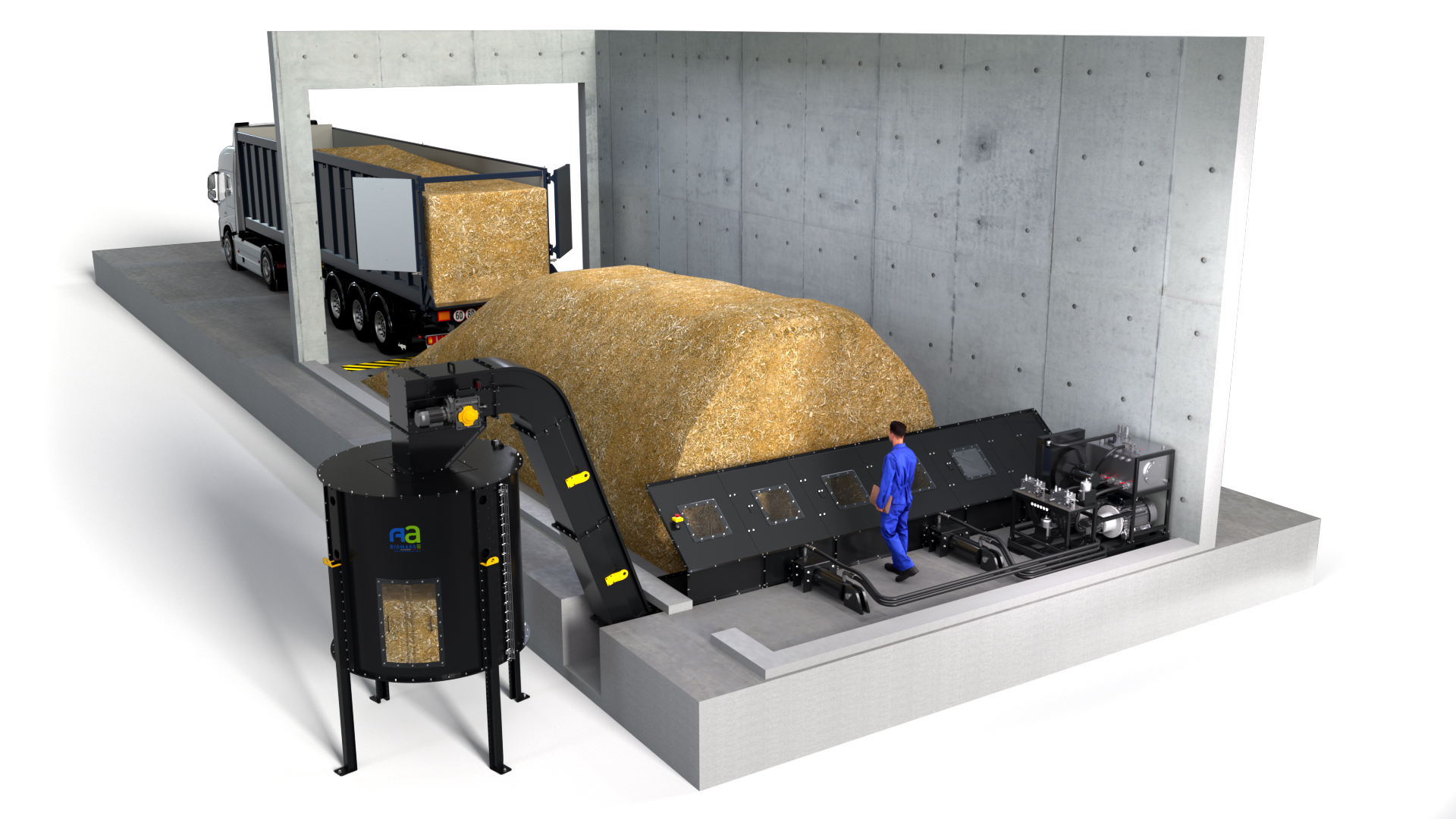

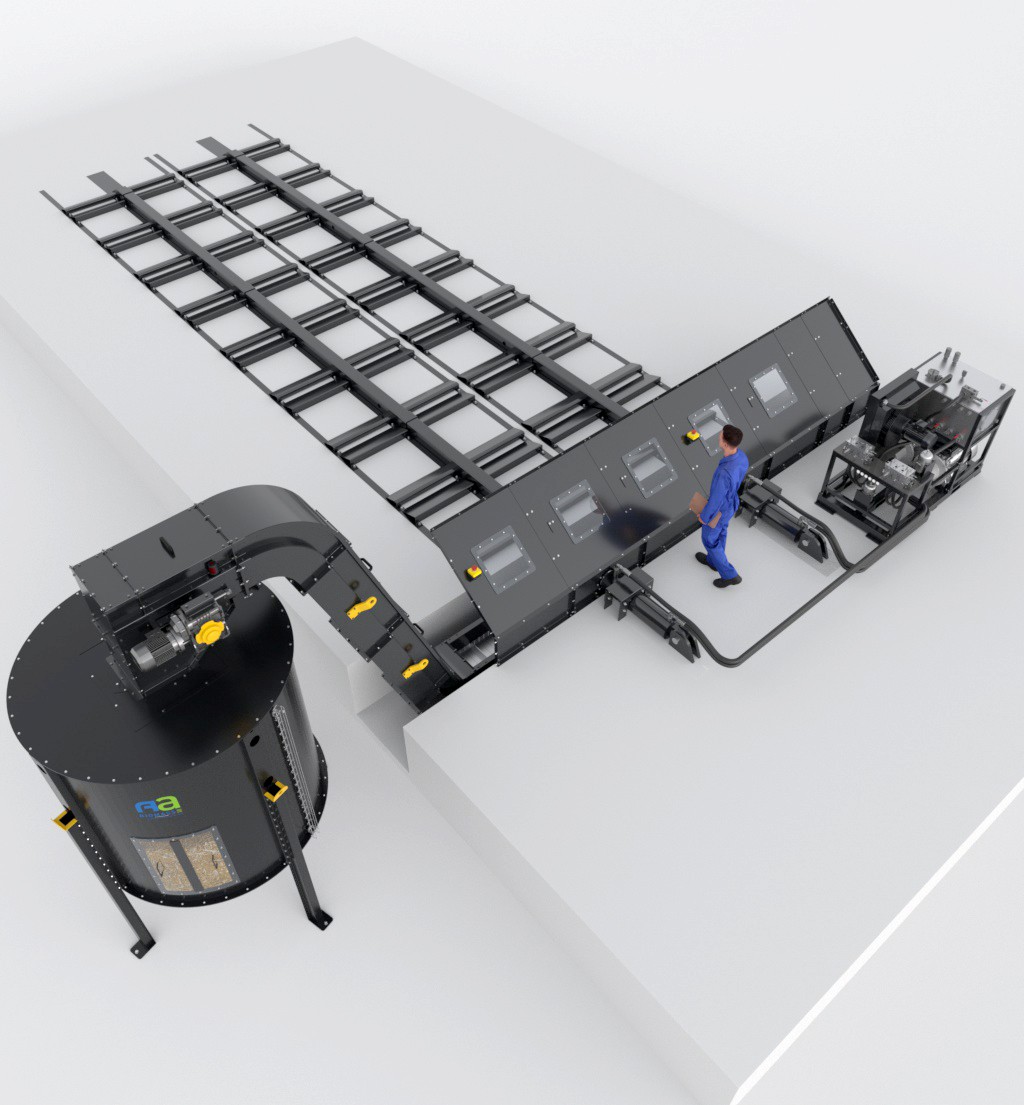

The drive-over ladder silo is a robust and modular solution that allows trucks to drive directly over the silo and unload biomass without intermediate handling. Designed for demanding industrial sites, this system ensures a regular, automated, and uninterrupted supply to boilers or process lines.

Direct Unloading and Drive-Over Structure

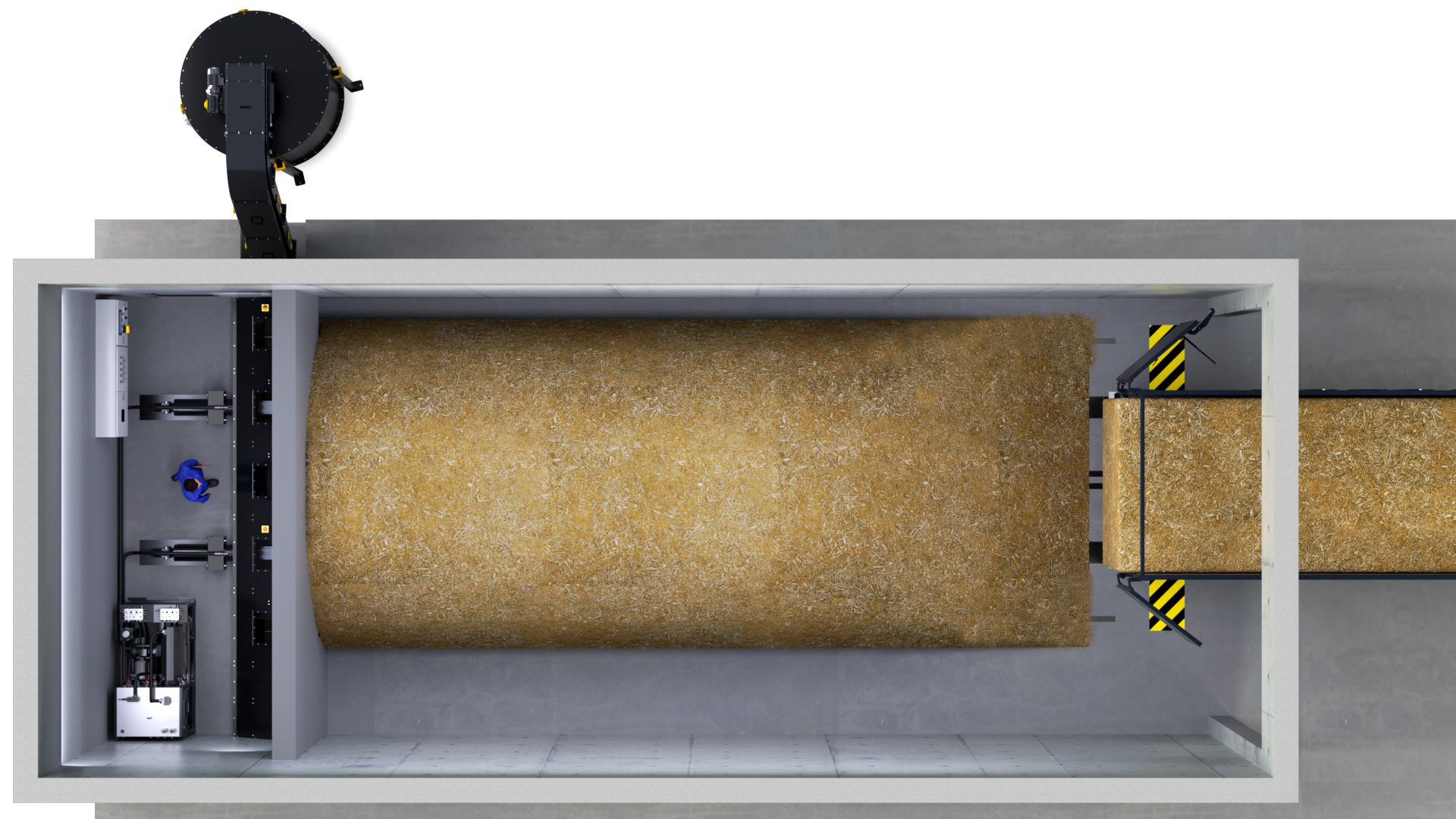

The silo is equipped with a floor made of reinforced ladders capable of withstanding the passage of heavy vehicles. After unloading, the biomass falls directly into the storage volume, eliminating waiting times and simplifying supply logistics.

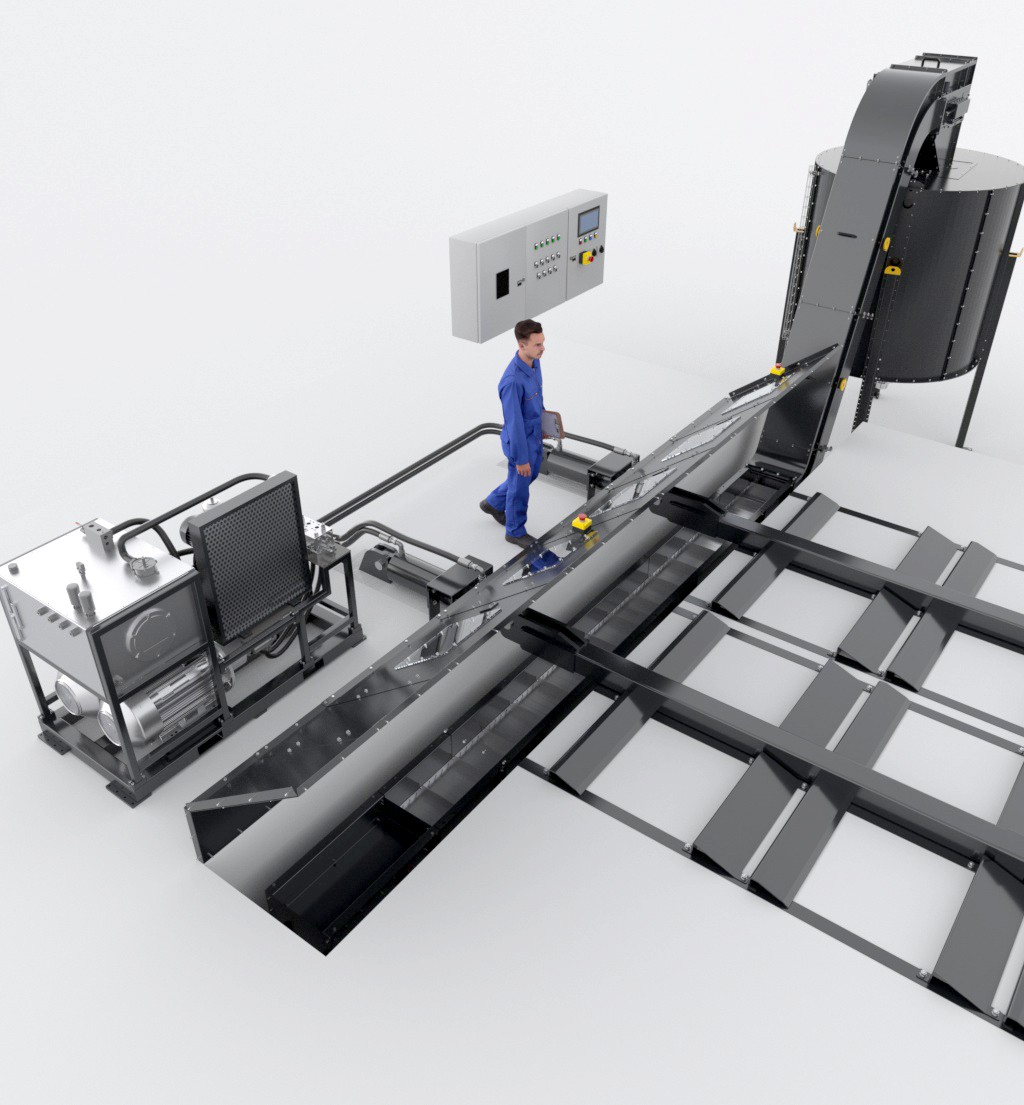

High-Power Motorized Ladders

The ground-level ladders are driven by hydraulic cylinders with a traction capacity exceeding 50 tons, enabling the gradual and consistent advance of biomass towards the extraction conveyor.

This step-by-step movement prevents blockages, streamlines the flow, and ensures perfectly controlled dosing.

Modular Construction

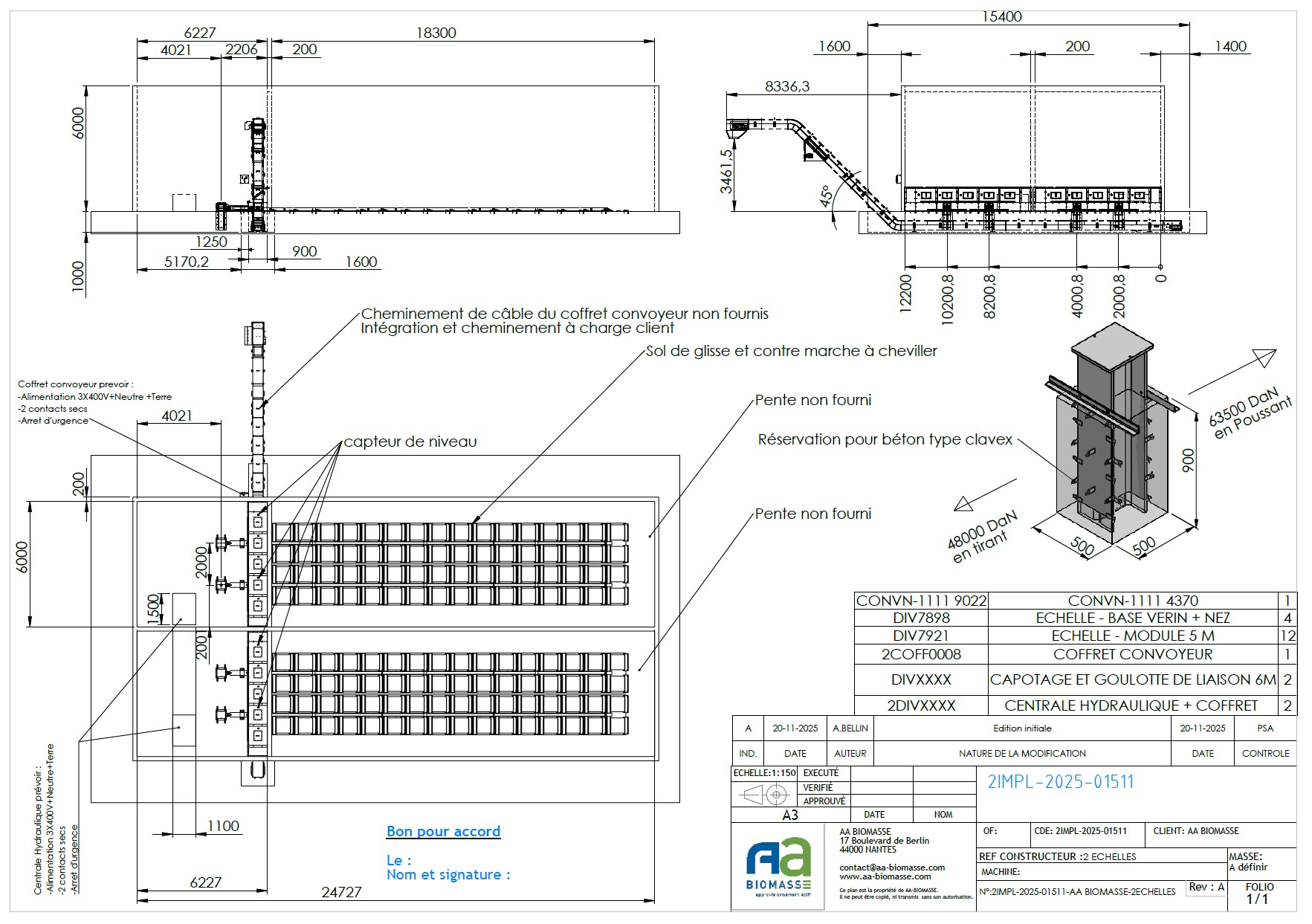

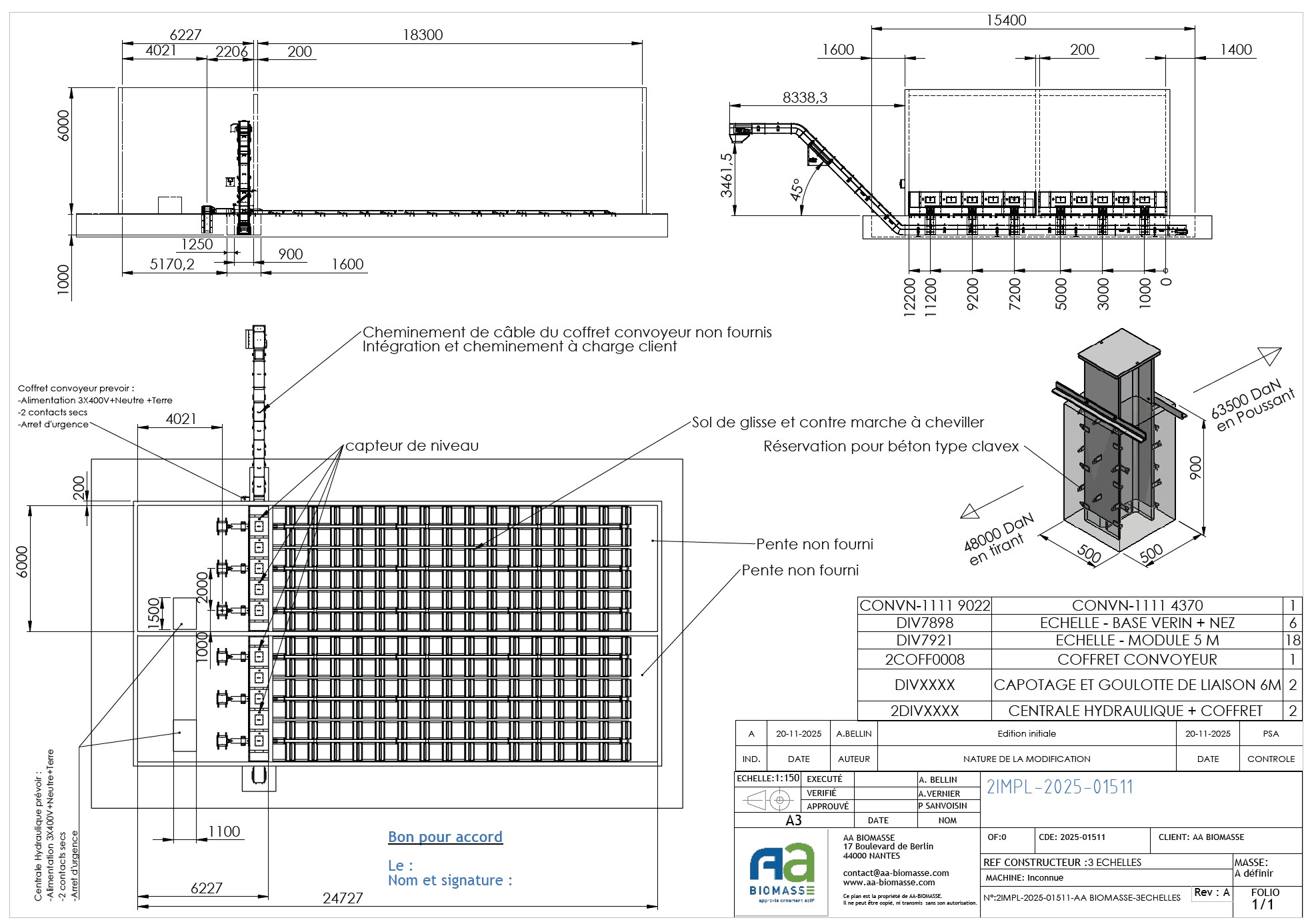

The system is fully modular, allowing for easy adaptation of the width and length, as well as the internal configuration of the silo, to meet the needs of each industrial site. The installation can therefore be integrated into existing buildings or new projects with minimal civil engineering work.

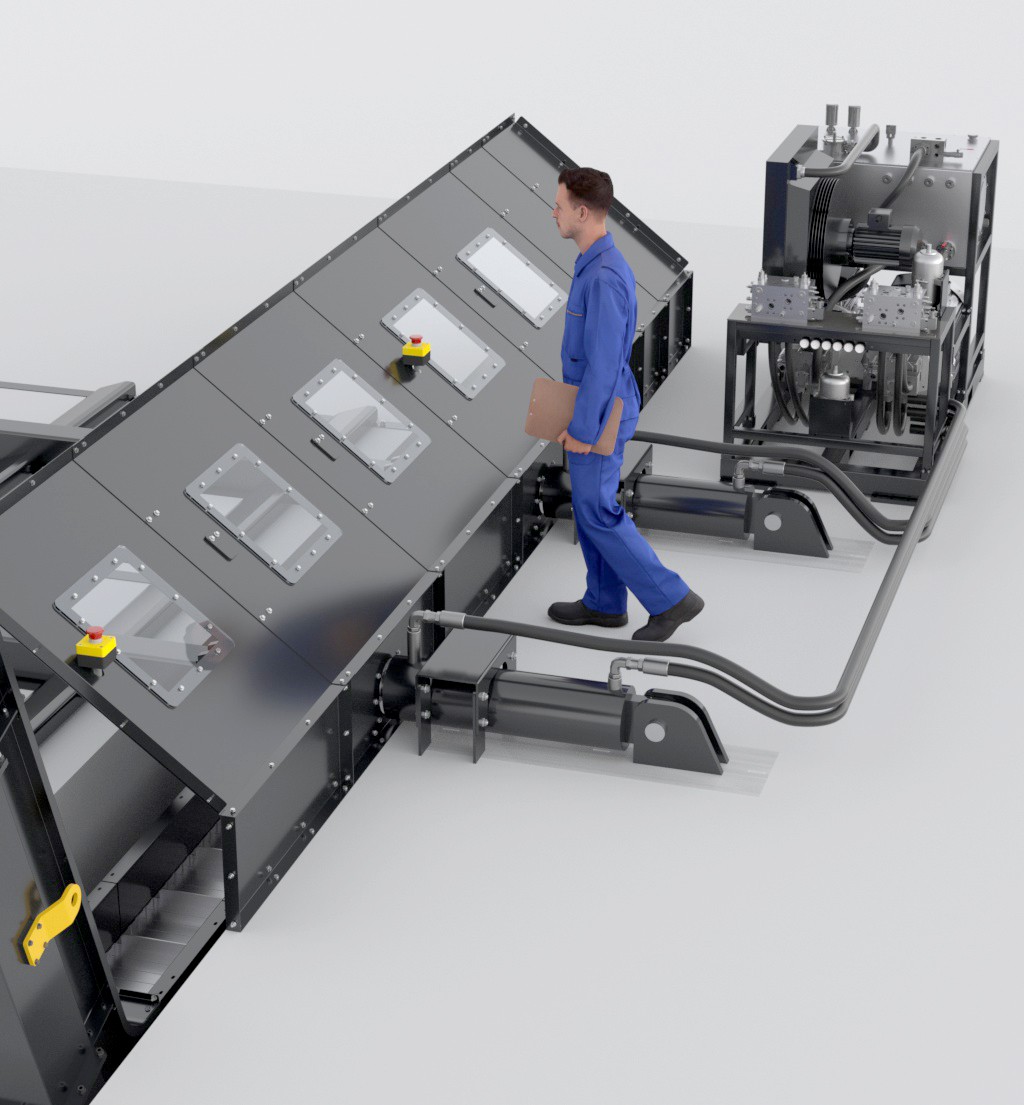

Integrated Extraction Conveyor

At the ladders' exit, the boiler feed conveyor is protected within an upper enclosure that includes viewing windows to allow the operator to monitor the flow, provides easy access for maintenance, and offers complete protection against dust.

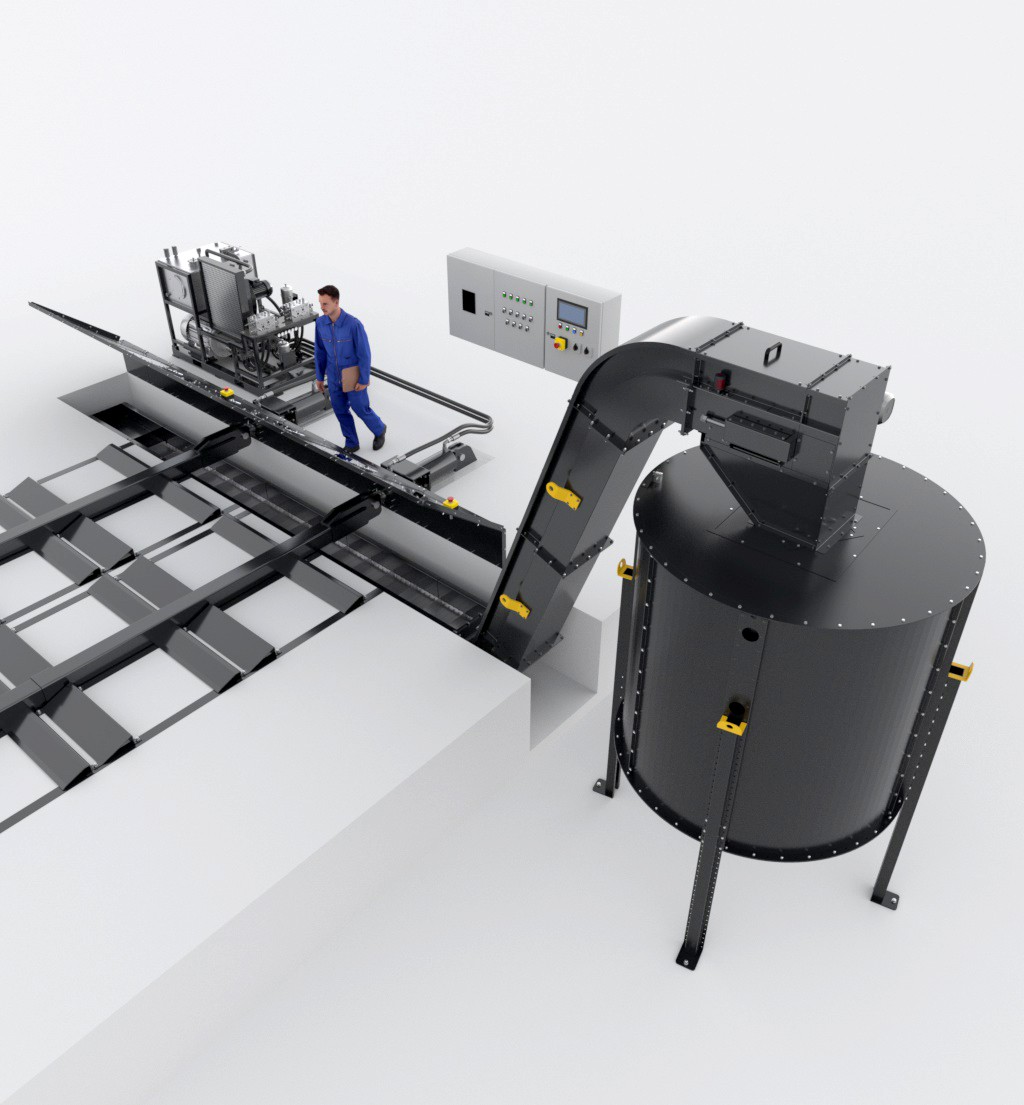

Hydraulic Control and Complete Automation

The entire system is controlled by a hydraulic power unit connected to an automated control cabinet.

The controller coordinates the movement of the ladders using synchronized step-by-step sequences.

System start-up relies on intelligent detection:

Vision sensors continuously monitor the biomass level in the feed conveyor.

As soon as the conveyor empties, the ladders automatically begin moving to refill it.

This ensures the boiler receives a constant, stable feed perfectly tailored to its needs.

Direct truck unloading

Robust, road-ready structure

High-power hydraulics (cylinders > 50 tons traction)

Progressive, blockage-free advance of biomass

100% modular construction adaptable to all dimensions

Easy visual monitoring thanks to the glazed enclosure

Full automation controlled by intelligent sensors

Reliable and continuous boiler feed