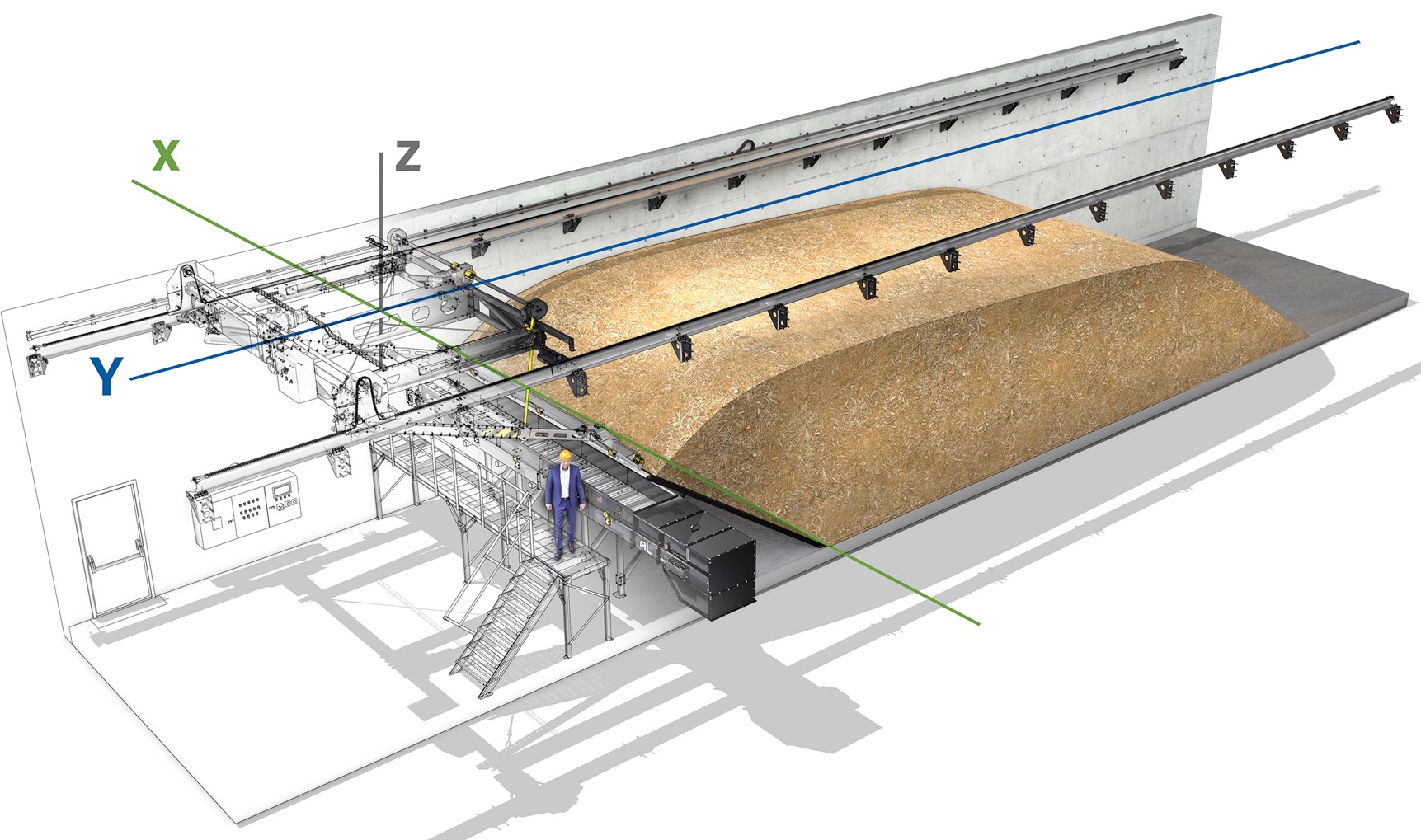

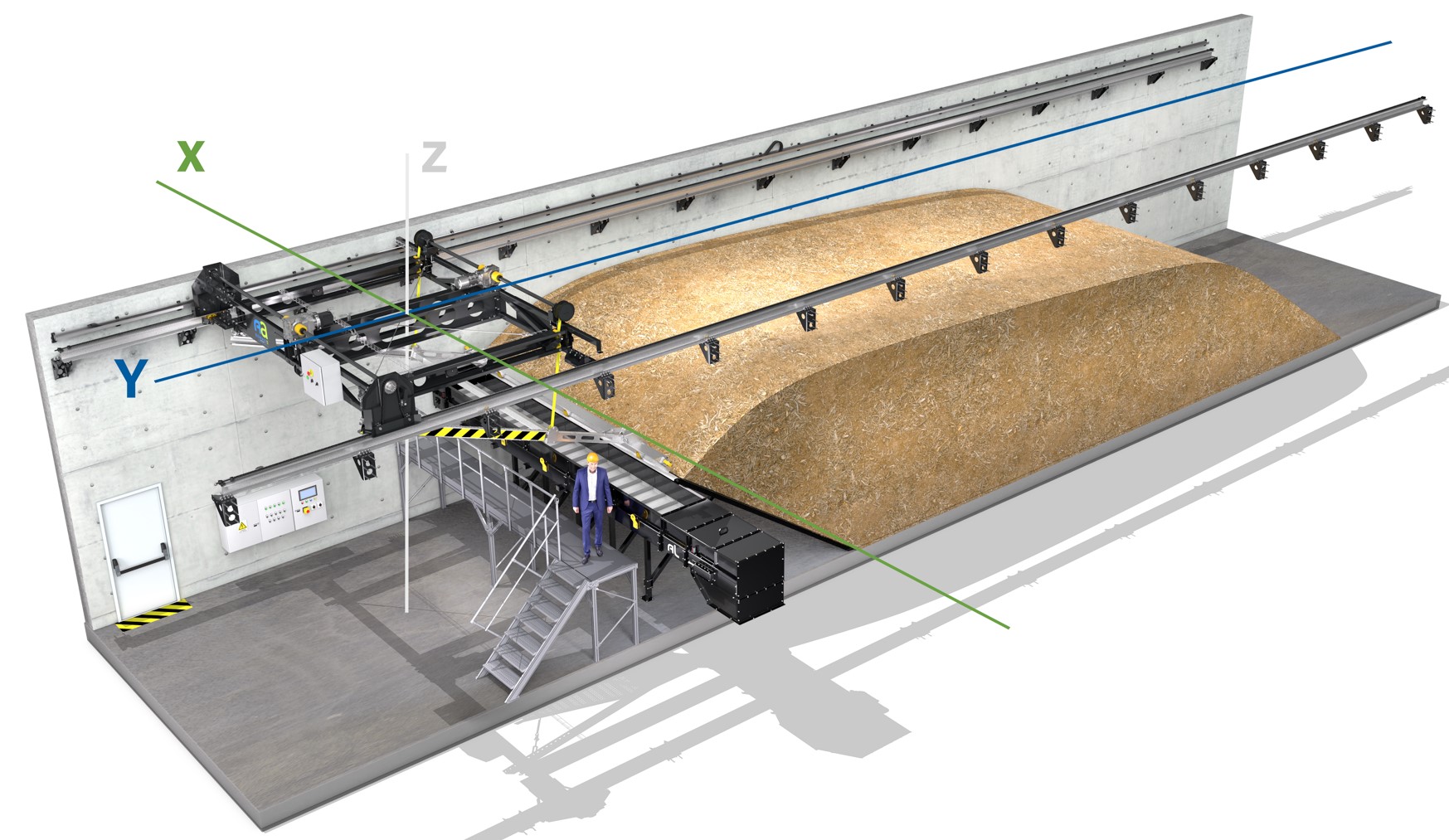

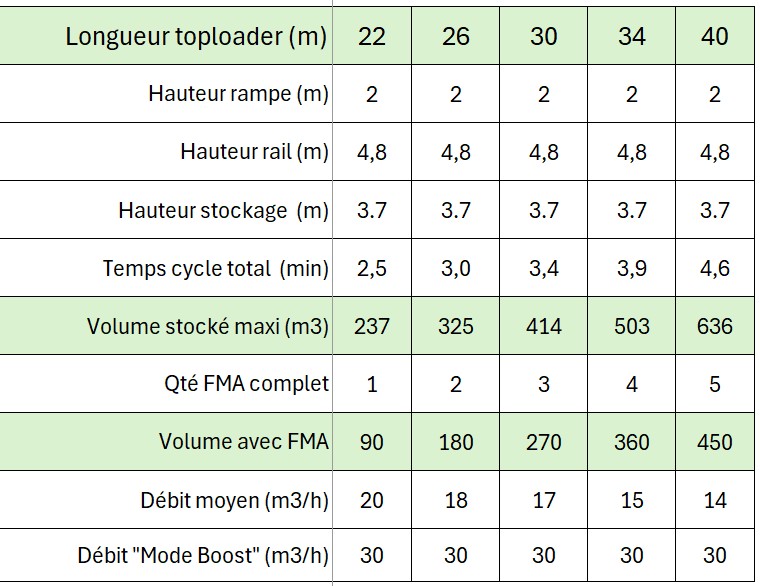

Wood and biomass toploader Capacity 300 M3

Toploader – The simple, robust and automatic solution for biomass storage

The AA-Biomass Toploader is an automatic rake silo designed for large-scale storage and continuous biomass feeding without human intervention. Installed at ground level, it offers an economical and reliable alternative to traditional silos or complex hydraulic systems.

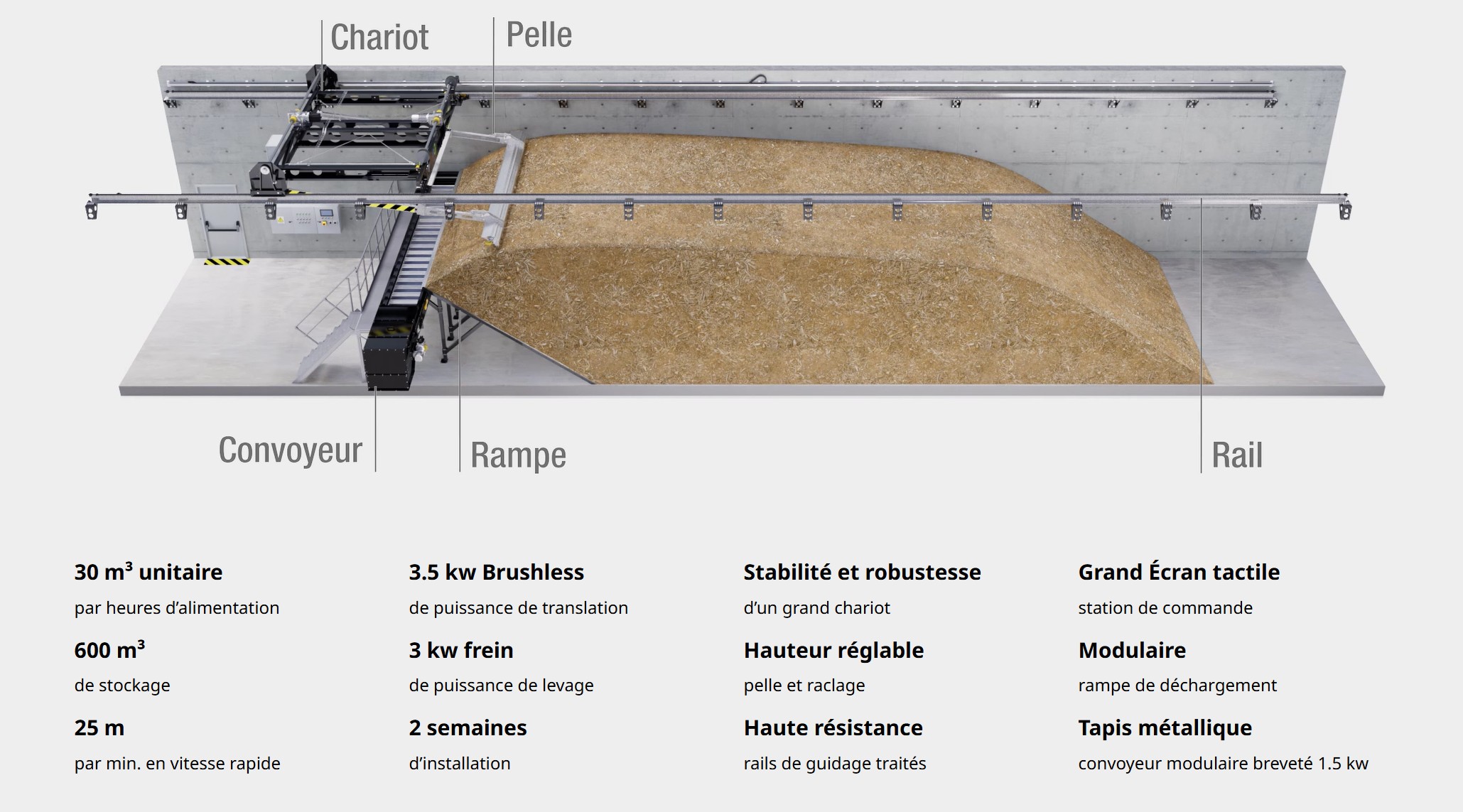

Operation

Direct unloading from the truck into an open silo.

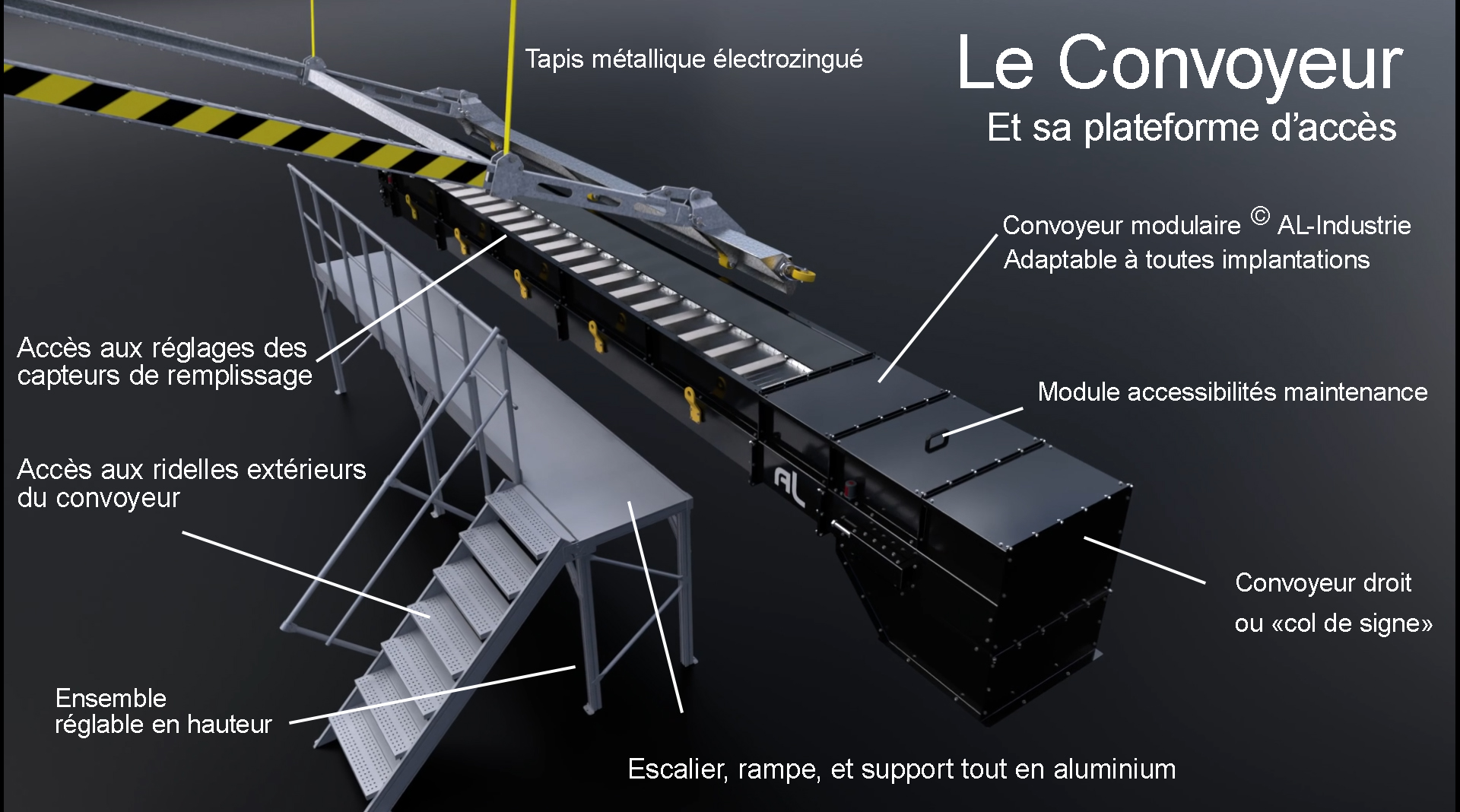

An automated rake-equipped cart moves the biomass and conveys it to an extraction conveyor.

Continuous supply to the boiler or process, 24/7.

Key Advantages

Rapid installation: minimal civil engineering work, commissioning in just a few days.

Large capacity: up to 600 m³ of storage.

High throughput: up to 30 m³/h.

Ultra-reliable: simple mechanism, low wear, reduced maintenance. Versatile: suitable for wood chips, wood waste, RDF, biofuels…

Made in France: design, production and after-sales service 100% carried out in France.

Applications

Industrial and district biomass boilers

Heating networks

Gasification/pyrogasification

Wood industry, RDF, recycling, waste treatment

In summary

The Toploader is the ideal solution for facilities seeking simple, economical, and automated storage capable of handling large volumes of biomass with exceptional reliability.

SIEMENS Automatic Control – 9" TFT

Intelligent, intuitive, and secure TopLoader management

✔ Control Architecture

1 control cabinet with 9" SIEMENS touchscreen

1 trolley control box with integrated hydraulic cylinder

1 driver control box for silo access safety

Enhanced protection: dust, splashes, impacts

✔ Siemens S7-1200 PLC

Centralized data and parameter management

Complete SCADA: monitoring & data acquisition

Reported information: TopLoader status, total volume, operating/fault time…

MODBUS or PROFINET communication

✔ Advanced Human-Machine Interface

9" TFT touchscreen, 16 million colors, PROFINET

Secure manual management via password

Clear interface: color coding, explicit messages

Display: current cycle, stacking, volume + curve, sensor status

Remote access: web page or EWON VPN eCatcher

✔ 5 operating modes (standard)

Automatic: Stacking and feeding managed independently

Manual: Maintenance and intervention

Stacking: Storage without feeding

Boost: Rapid feeding without stacking

Remote: Multi-zone management (2 zones)

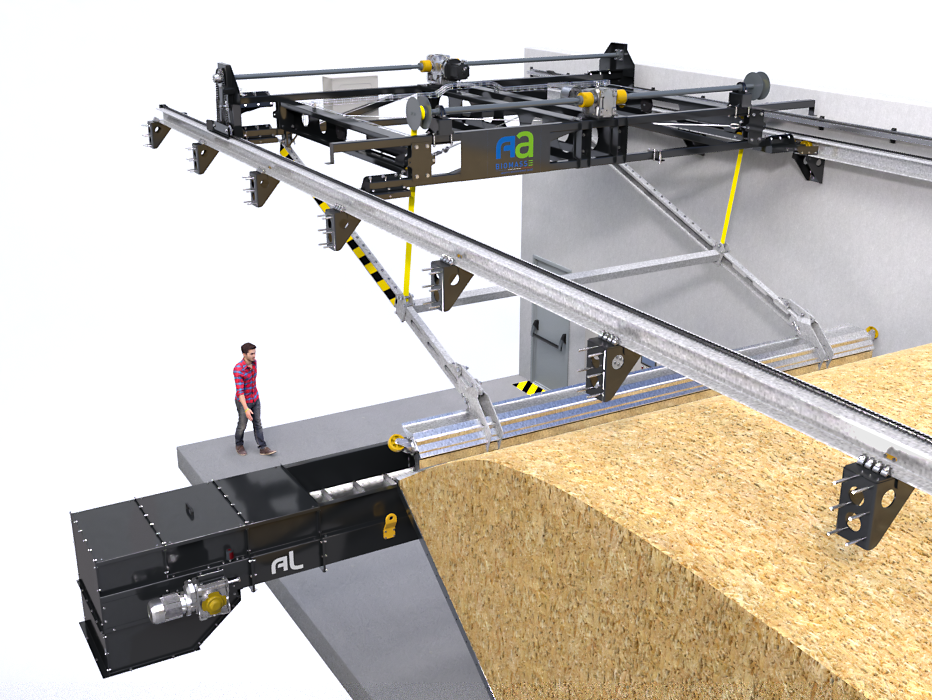

✔ Driver Control Panel

Controls the position of the forklift before opening the silo

Secures delivery without access to the boiler room

100% French manufacturing – Premium industrial quality

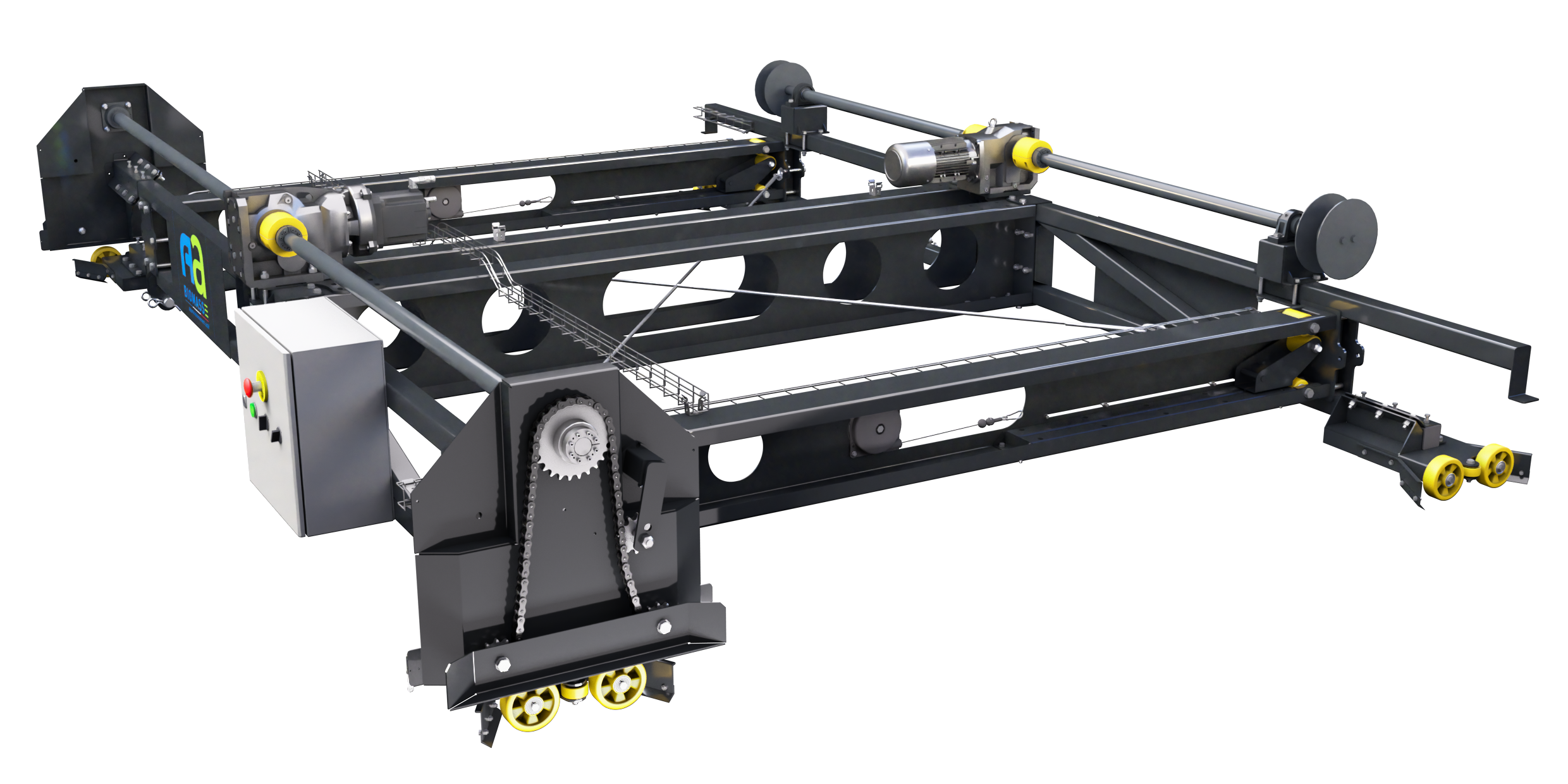

✔ Performance & Precision

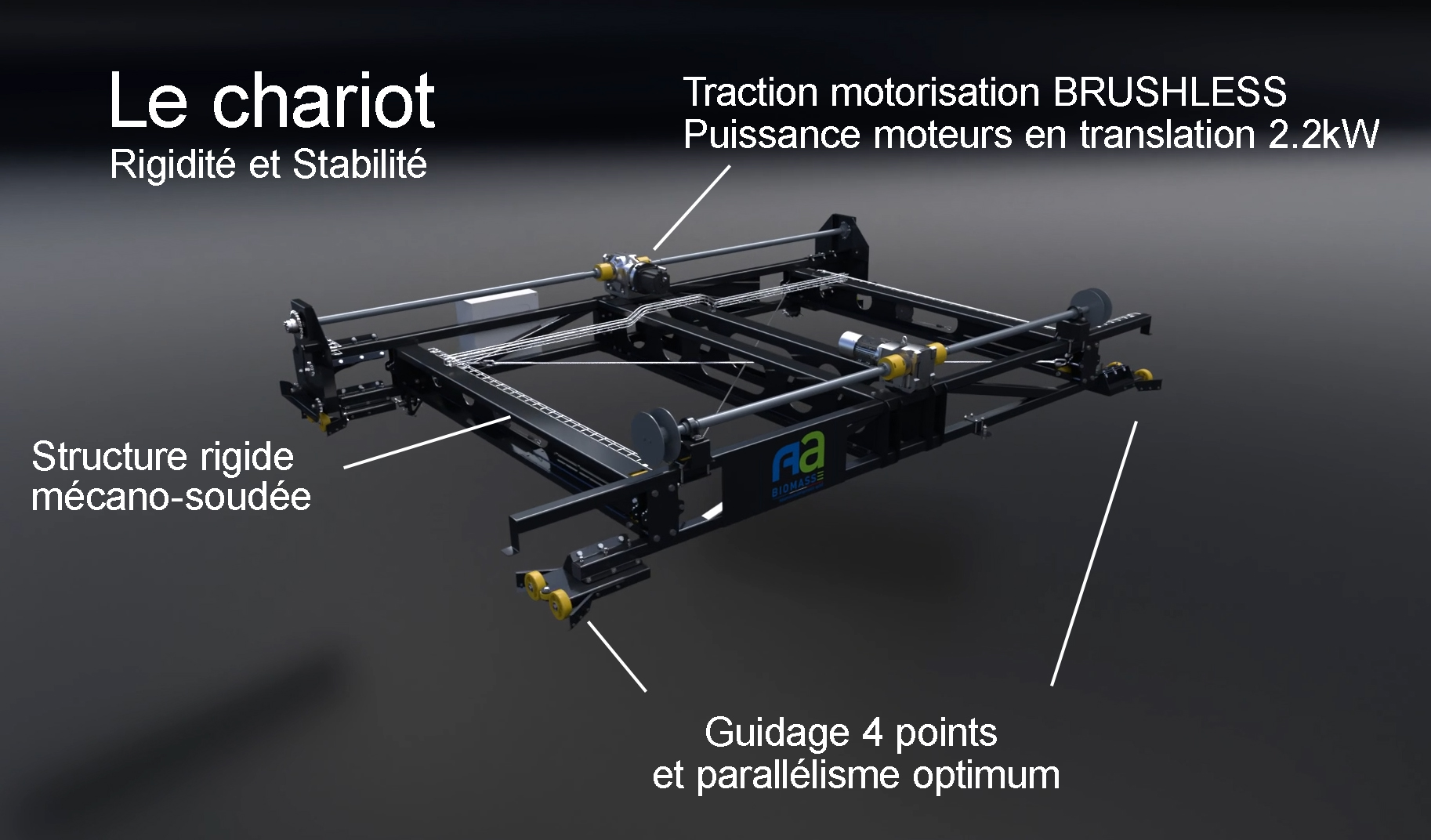

Brushless motor: ultra-precise positioning

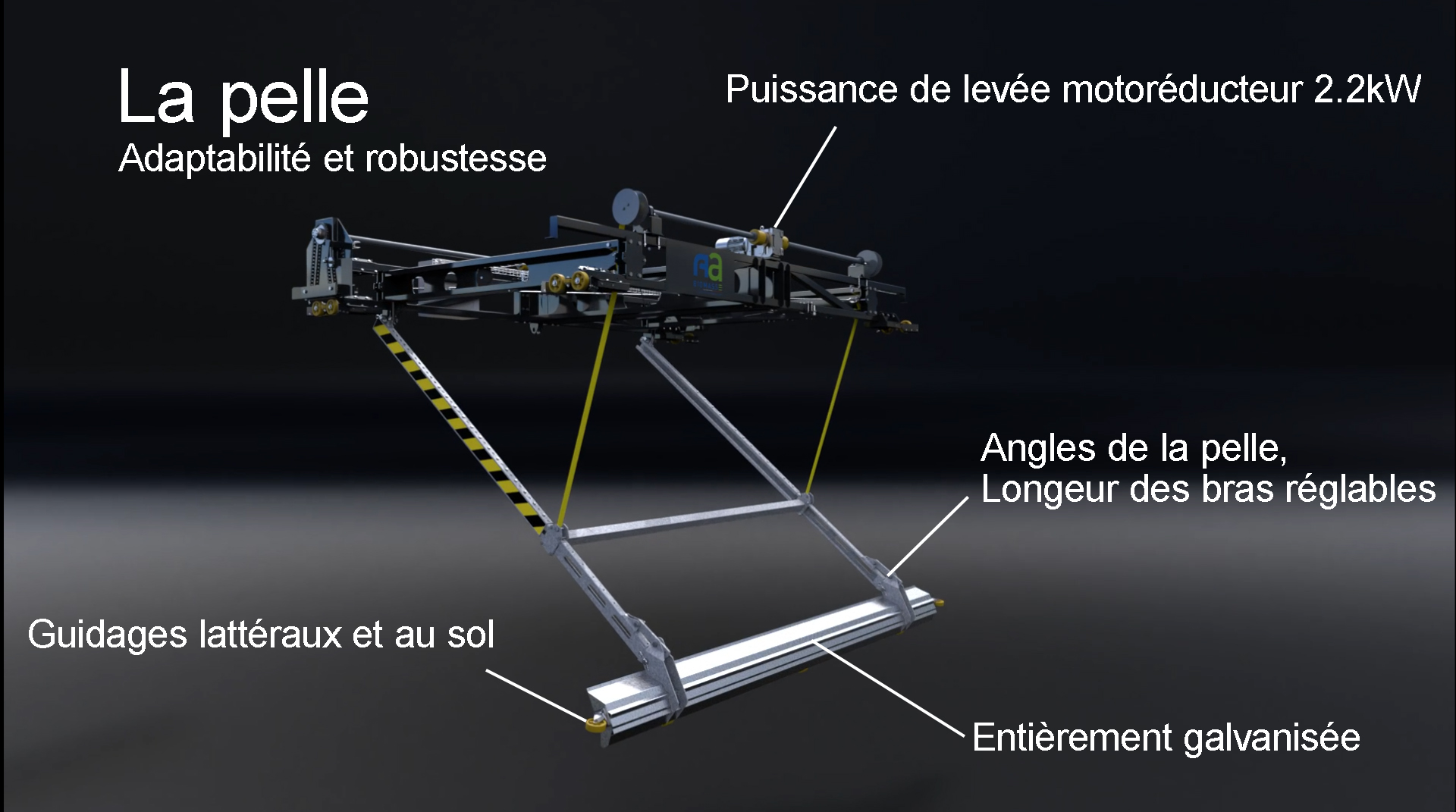

Shovel encoder: optimized silo approach

Boost and FIFO modes: fast feeding & multi-zone management

✔ Robustness & Durability

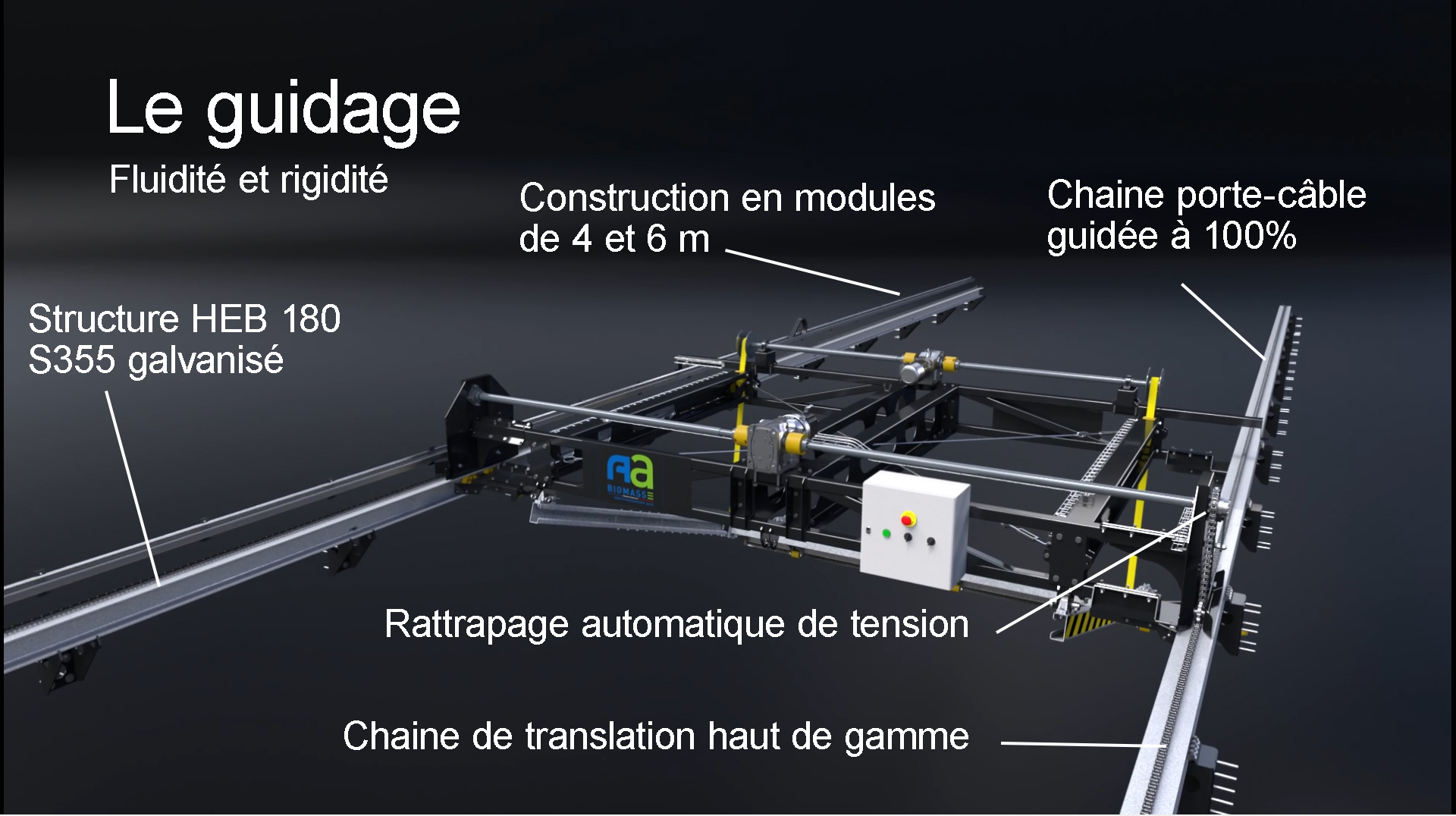

Galvanized HEB 180 rails

High-performance wheels (double bearings)

Cable carrier chain for lower buildings

✔ Immediate productivity

Automatic belt pre-tensioning

Integrated horizontal control

Adjustable shovel length & tilt (3 positions)

Scraper ladder program included

Onboard jack for machine diagnostics

✔ Connectivity

Data transfer included via exchange table

- description

Télécharger top0101-aa6-h4-8-l22-6935b861280bd111897546.pdf

- description

Télécharger top0102-aa6-h4-8-l24-6935b86129db3929880679.pdf

- description

Télécharger top0103-aa6-h4-8-l26-6935b910d087f141698990.pdf

- description

Télécharger top0104-aa6-h4-8-l28-6935b910d1843099864605.pdf

- description

Télécharger top0105-aa6-h4-8-l30-6935b910d248f285287649.pdf

- description

Télécharger top0106-aa6-h4-8-l32-6935b910d30f4992857160.pdf

Our projects

17 août 2024

Biomass heating plant in Passy, 74

18 août 2024

Biomass heating plant Prytanée national militaire de La Flèche 72

16 octobre 2024

Groupe SEB's biomass boiler room

28 mars 2025

The IUT of Belfort has equipped itself with the AA-Biomasse Toploader, 100% made in France.

15 novembre 2024

A new Biomasse AA Biomasse toploader installed in Belfort for Tandem Immo!

6 février 2026